Some time ago there was a thread regarding a publication by the Packard Automobile Club entitled, “The Packard Cormorant” where the Winter 2009 edition was devoted to the rise and fall of 1580 East Grand Boulevard. Many authors contributed to the publication and one author in particular [[AJB) wrote an article about the use of the various buildings in the Packard complex.

In his article AJB describes that the buildings were dynamic, that is PMCC changed their use over time as need dictated. AJB and a friend acquired a large roll of drawings at a flea market about the use of the Packard Plant several decades ago. I consider AJB a friend and in a phone call tonight reminded me that his article is copyright protected, but that I could discuss some parts of it here.

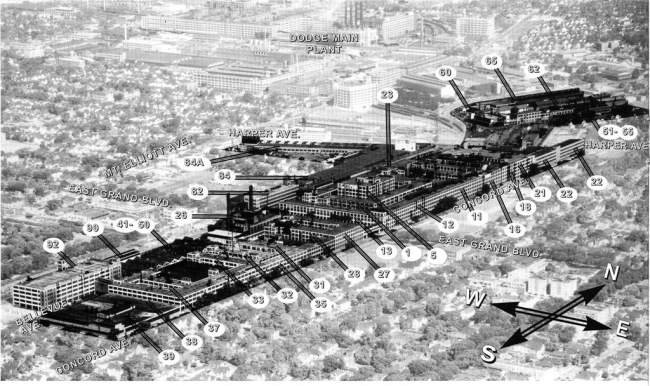

Attached is a scan of the PMCC Plant circa 1949. Please use this birdseye view as a reference.

After re-reading the article I can tell you what was going on in 1949 and on what floor:

Building 11: 2) Motor assembly, 3) Front fender and grille assembly and wheel paint, and 5) Hardware painting and ovens

Building 12: 1) Dynamometer lab, 2) Body Handling [[Body Drop?), 3) Paint Office, 4) Production control, 5) Misc, hardware/paint

Building 15: 2) Motor parts machining, 3) Material storage, 4&5) Paint, bonnet and fender

Building 16: 1) Final assembly line/paint repair, 2) Motor assembly 4) Painted front clip storage, 5) Hardware; paint and ovens

Building 22: 1) car prep and final repair, 2) Personnel and restaurant, 3) Service Engineering, 4) Chassis and body engineering and Styling. Note: during WWII this was the building constructed for the Merlin/Packard aircraft engine where Georgem’s mother worked.

Prior to WWII the car body plant was south of EGB and the bodies were rolled on dollies over the EGB bridge. The bodies arrived on the second floor of Building 12 and then to the drop point. The final assembly of the completed car was on the first floor of Builing 16.

After WWII [[from 1946 to 1954) Packard bodies were built by the Briggs Manufacturing Company at their Conner Avenue plant and transported to the PMCC on EGB for trimming and storage prior to final assembly.

For 1955 and 1956 all assembly work for Packard was moved to the Conner Avenue plant. The major reason Packard turned over body building to Briggs was that they simply did not have the space at the boulevard plant.

Results 1 to 16 of 16

Threaded View

-

January-24-11, 09:05 PM #5

DetroitYES Member

DetroitYES Member

- Join Date

- Jan 2010

- Posts

- 645

Welcome to DetroitYES! Kindly Consider Turning Off Your Ad BlockingX

DetroitYES! is a free service that relies on revenue from ad display [regrettably] and donations. We notice that you are using an ad-blocking program that prevents us from earning revenue during your visit.

Ads are REMOVED for Members who donate to DetroitYES! [You must be logged in for ads to disappear]

Ads are REMOVED for Members who donate to DetroitYES! [You must be logged in for ads to disappear]

DONATE HERE »

And have Ads removed.

And have Ads removed.

Reply With Quote

Reply With Quote

Bookmarks